June 1, 2023

3D Printing and Modular Building - Future of Construction Industry

The construction industry has always been marked by innovation, and in recent years, 3D printing and modular construction techniques have emerged as transformative technologies. These advancements have the potential to revolutionize the way buildings are designed and constructed, offering numerous benefits such as cost savings, reduced construction time, and increased design flexibility.

But the question is what is their future in construction?

Therefore, to help you understand this query in this article, first we will explore what 3D printing and modular techniques in construction are, then their current state and then we will delve into the future they hold in construction.

What are 3D printing and modular techniques in the construction industry?

3D printing and modular techniques are innovative approaches used in the construction industry to optimize the building process.

By attending the construction technology event, you can learn more about how these techniques optimize the construction process.

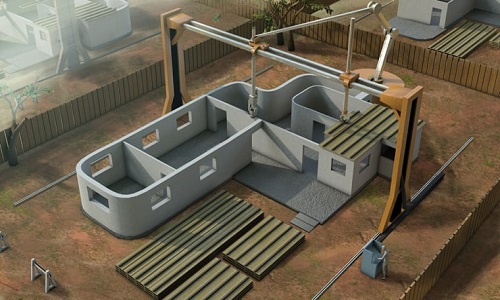

But in a short explanation for both, we would say 3D printing uses large-scale printers to create objects by depositing material layers. It allows for the quick fabrication of building components with customization, speed, cost savings, design flexibility, and sustainability.

However, modular techniques involve assembling prefabricated modules off-site for reduced construction time, enhanced quality control, cost savings, flexibility, and sustainability.

Both approaches aim to improve efficiency, reduce costs, and enhance sustainability. 3D printing focuses on on-site fabrication, while modular techniques emphasize off-site manufacturing and assembly of standardized modules, complementing each other in advancing construction practices.

What is the impact of 3d Printing and Modular Building Techniques Construction?

At the Construction Technology Festival, experts highlight the impact of 3D printing and Modular Building Techniques in construction by its advantages and challenges. Some of which we have mentioned below for both in different sections. Keep reading.

3D Printing in Construction

Advantages of 3D Printing in Construction:

- Customization: 3D printing enables the creation of highly customized designs and intricate architectural elements that would be challenging to achieve using traditional construction methods.

- Speed and Efficiency: The layer-by-layer additive manufacturing process of 3D printing can significantly reduce construction time compared to conventional approaches, leading to faster project completion.

- Cost Savings: By optimizing material usage and reducing labor requirements, 3D printing has the potential to reduce construction costs.

- Design Flexibility: Complex and unique shapes can be easily created using 3D printing, allowing architects and designers to explore innovative design possibilities.

- Sustainable Construction: Additive manufacturing can minimize material waste by using only the required amount of materials, promoting sustainability in construction.

Challenges 3D Printing faces

- Scale and Size Limitations: Scaling up 3D printing for large-scale buildings or infrastructure projects remains a challenge. Current technologies may not be capable of producing structures beyond a certain size efficiently.

- Structural Integrity and Quality Assurance: Ensuring the structural integrity and long-term durability of 3D-printed components is crucial. Rigorous testing and quality assurance processes are needed to meet safety standards.

- Integration of Utilities: Incorporating plumbing, electrical systems, and other utilities into 3D-printed structures requires careful planning and coordination to ensure proper functionality.

- Regulatory and Legal Considerations: As 3D printing in construction becomes more prevalent, regulatory frameworks and legal standards need to be established to address safety, liability, and compliance requirements.

Modular Construction

Advantages of Modular Construction

- Time Efficiency: Constructing buildings using prefabricated modules significantly reduces on-site construction time, as modules are manufactured simultaneously with site preparation, leading to faster project completion.

- Quality Control: Modular construction takes place in controlled factory environments, allowing for stringent quality control measures and ensuring consistent construction standards.

- Cost Savings: Streamlined manufacturing processes, reduced material waste, and enhanced labor efficiency contribute to potential cost savings in modular construction projects.

- Flexibility and Adaptability: Modular buildings are designed with flexibility in mind, allowing for easy expansion, modification, or disassembly as needs change over time.

- Sustainability: The off-site manufacturing process in modular construction results in less material waste and disruption to the site. Additionally, modules can be recycled or repurposed, promoting sustainability.

Challenges

- Transportation and Logistics: Coordinating the transportation and delivery of large modular components to the construction site requires careful planning, especially for projects in remote or challenging locations.

- Design Limitations: Modular construction may have some design limitations due to standardized module sizes and shapes, although advancements in modular design are expanding the range of possibilities.

- Site Preparation and Integration: Proper site preparation, including foundation work and utility connections, is essential to ensure smooth assembly and integration of modular components.

- Architectural Aesthetics: Achieving architectural diversity and customization in modular construction can be a challenge, as modular buildings may have a standardized appearance.

However, it is important to keep note that ongoing research, technological advancements, and industry collaborations which were also the part of discussion at the Construction Networking Event in UAE are continually addressing these challenges and driving further progress in both 3D printing and modular techniques in construction.

The Future of 3D Printing and modular techniques in Construction

Well, if we talk about the future then 3D painting and modular techniques in construction hold great potential for advancements in the industry. Below we have separately mentioned some possibilities of 3D painting and modular building techniques:

3D Painting:

- More accessible and sophisticated: With the advancement of technology, 3D painting techniques will likely become more sophisticated and accessible. This could involve the use of augmented reality (AR) or virtual reality (VR) tools to create immersive painting experiences. Artists and designers may be able to paint directly onto virtual 3D models, allowing for a more intuitive and efficient design process.

- Customization and Personalization: 3D painting techniques can enable greater customization and personalization in construction projects. Artists and designers will be able to create unique and intricate patterns, textures, and finishes that were previously challenging to achieve. This can lead to more aesthetically pleasing and visually appealing buildings and structures.

- Sustainability and Environmental Considerations: 3D painting techniques can contribute to sustainability efforts in construction. The use of environmentally friendly paints and coatings can reduce the environmental impact of painting processes. Additionally, 3D painting techniques can be employed to create solar-reflective or heat-absorbing surfaces, contributing to energy efficiency in buildings.

Modular building Techniques:

- Modular construction: It involves the use of prefabricated building components that are manufactured off-site and assembled on-site. This approach offers numerous advantages, such as reduced construction time, cost-effectiveness, and improved quality control. In the future, modular techniques may become even more advanced, allowing for greater design flexibility and scalability. This could involve the use of advanced robotics, 3D printing, or other automated processes to fabricate modular components.

- Integration of Smart Technology: The future of modular construction may also involve the integration of smart technology. Modular components could be designed to incorporate sensors, connectivity, and automation, enabling buildings to adapt and respond to changing environmental conditions. This can result in improved energy efficiency, enhanced comfort levels, and better overall building performance.

- Enhanced Safety and Durability: 3D painting and modular techniques can contribute to improved safety and durability in construction. High-performance coatings and finishes can provide enhanced protection against weathering, corrosion, and fire. Modular construction, with its controlled manufacturing environment, allows for rigorous quality control and ensures that building components meet stringent safety standards.

Overall, the future of 3D painting and modular techniques in construction is likely to involve increased customization, sustainability, and integration of advanced technologies.

Conclusion

The future of the construction industry is being reshaped by 3D printing and modular building techniques. With their ability to optimize efficiency, cost-effectiveness, and sustainability, these innovative approaches are set to revolutionize how buildings are designed and constructed. As they continue to evolve and gain wider adoption, 3D printing and modular techniques hold immense potential for transforming the construction industry into a more efficient, sustainable, and technologically advanced sector.

However, if you ever had an opportunity to attend the Construction Networking Event, never miss it as it is the leading place where you can gain insights into these exciting technologies and connect with industry experts.

Just Say Hi there!